VAD Impeller Design

Introduction

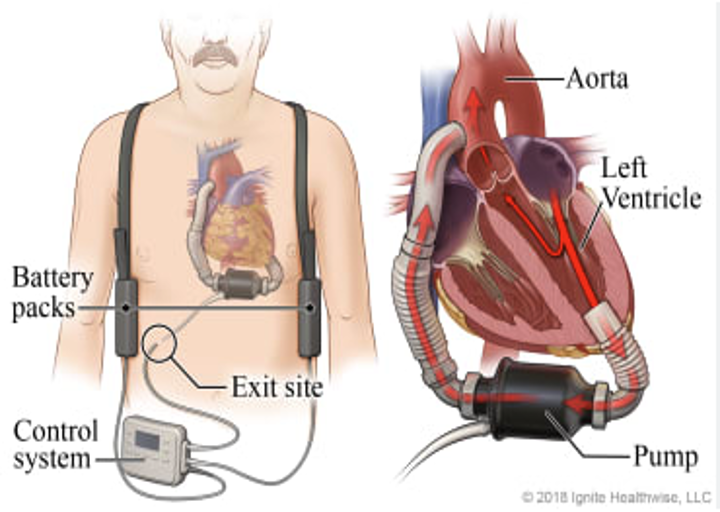

This design project focuses on developing a high-performance impeller in the pump of a Ventricular Assist Device (VAD). This device assists hearts failing from cardiovascular diseases (e.g., congestive heart failure). Currently, the design focuses on assisting the left ventricle for relatively long periods (e.g., decades). The goal is to meet stringent requirements for efficiency, durability, and biocompatibility while remaining economically viable for production.

Design

- Operating Parameters:

- Continuous operation for a decade.

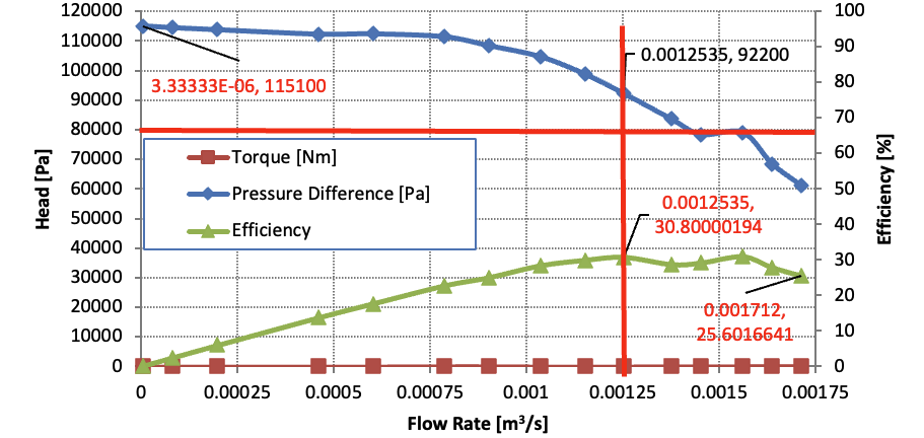

- Pumps blood at 75 liters/min with a pressure difference of 0.80 bar.

- Materials:

- Lightweight and biocompatible.

- Chosen for compatibility with fluids and organs in the human body.

My Contribution

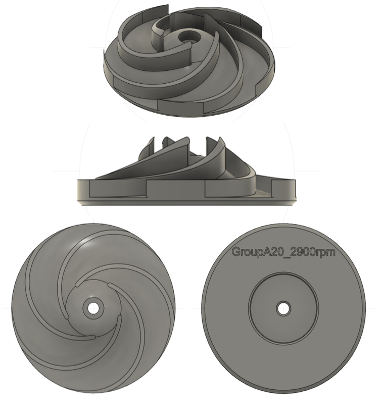

Each team member explored impeller designs at various speeds (2400-3000 rpm), optimizing parameters such as blade height, slip factor, and velocity match. I’m responsible for the design of impeller at the speed of 2700 rpm.

I used Excel and MATLAB for calculations and Fusion 360 for CAD modeling. The Materials were selected using CES for biocompatibility, strength, and thermal properties. Then I select the manufacturing process based on the material selection and use Eco-Audit to analyze the material and lifecycle of the proposed design.

Final Recommendations:

- Mechanical Design: 5-blade impeller, optimal speed at 2900 rpm.

- Material: Titanium ASTM F-136 (high biocompatibility, corrosion resistance).

- Density: 4.41 g/cm³

- Young’s Modulus: 110-119 GPa

- Yield Strength: 786-910 MPa

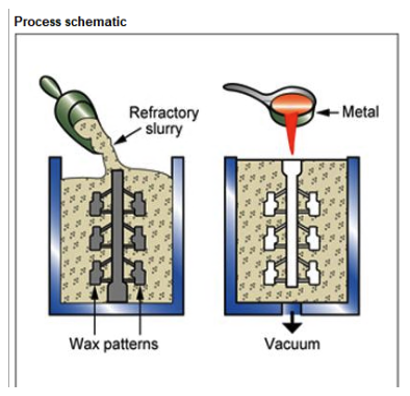

- Manufacturing Process: Investment casting.

Evaluation

The prototype was manufactured using investment casting and 3D printing (see figure below). Tests showed exceptional pumping efficiency under high-pressure conditions, outperforming other designs.

Conclusion

The proposed impeller design meets all functional, economic, and environmental criteria, offering a viable solution for long-term ventricular support. Future work could refine the flow dynamics and explore alternative manufacturing methods for enhanced scalability.